| Main page | Læs denne side på dansk |

|

Why does wood split and crack when it dries?

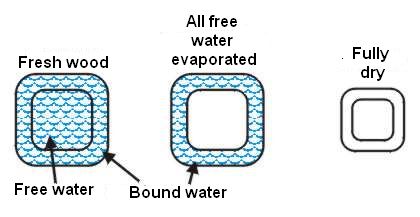

Wood is composed of cells that forms vessels (hardwoods/dicotyledons) or just a sponge-like structure (softwoods/conifers) that transports water and nutritients from the root to the leaves and and sugar from the leaves to the roots. Therefore, green/fresh wood is filled with water. This water is called free because it can move freely between root and leaves as in a pipe.Inside the cells is also water that is the body fluid of the cells, and in the cell walls is water too. This water is called bound water because it can't freely flow around. It gives a tension or pressure to the cells.

Usually, 50 % of the weight of a living tree is water, giving a (relative) moisture content of about 100 % (see definiton below). When a tree is felled no more water i supplied from the roots but water is evaporating to the surroundings so that the moisture content of the wood is reduced. The free water evaporates first. When all free water is evaporated the moisture content has been reduced to less than a third of the initial, about 30 %. Now the bound water starts to evaporate.

During the first part of the drying when the free water evaporates, there is no deformation of the wood. When the bound water starts evaporating, the tension of the cells is slowly reduced and the cells shrinks and gets narrower but the direction of the fibres prevents the cells from shrinking lengthwise, along the fibres of the wood.

From this, one would think that the tree won't shrink lengthwise (the direction where the cells don't shrink) and that it would shrink equally tangentially (around the perimeter/along the growth rings) and radially (from the bark to the pith). In this case there would be no tension in the wood from the shrinkage, and the wood would not change shape or crack during drying. However, the composition of the wood is more complicated. The following desciption is even simplified.

The wood doesn't only have fibres going along the trunk. There are also fibres going from the pith to the bark, the so-called medullary rays. These fibres are clealy seen on for example quartersawn oak, and they give the beautiful patterns seen on many quartersawn woods.

The cells of these fibres also shrink during drying. This gives a very smal amount of shrinkage in the lengthwise direction because these fibres shink in that direction. In addition, and more iimportant, these fibres don't shrink in the radial direction of the trunk (pith to bark) preventing some of the shrinkage from the main fibres. The shrinkage of the fibres of the medullary rays don't influnce the tangential shrinkage (along the growth rings) because they shrink as much in this direction as the ordinary fibres..

Hence, the wood doesn't shrink equally in the three directions: lengthwise, radially and tangentially. This is the reason for the deformation and cracking when wood dries. The illustration below shows how a trunk theoretically deforms from drying if a narrow slit is cut lengthwise from bark to pith. During the drying, this slit will open up. This experiment can be done using a disc sawn from a fresh trunk or branch.

If this slit isn't cut, there will build up tension in the trunk and cracks will form going in the direction from the bark towards the pith. For some wood species one or few cracks will form. For other species there will be numerous small cracks. If you have ever seen a dry trunk or branch, you probably have noticed this.

If a plank is sawn from the fresh trunk as shown in the bottom of the illustration above, the wood will still shrink most in the direction along the annual rings. This will lead to a warpage of the plank as shown. You can always find out in what directon wood will deform during drying by remembering that the annual rings will 'try' to fold the 'circles' out and contract between the circles.

The opposite happens if a dry plank is moved outside or just to a room with higher humidity. The fibres of the wood will absorb moisture from the air and the plank will warp in the opposite direction as the plank in the illustration.

For some wood species, the sapwood shrinks more than the heartwood, for example laburnum. This results in more drying cracks in the sapwood than in the heartwood.

The shrinkage of various wood species

There is quite a difference in shrinkage in the three directions (lengthwise, radially, tangentially) between different wood species. It also can vary between trees of the same species. The tangential shrinkage is typically twice the radial shrinkage and the lengthwise shrinkage only a tenth of the radial shrinkage. The table below gives examples of shrinkage for some common wood species. The shrinkage specified is from fully wet to fully dry. In practice, wood doesn't dry fully under normal conditions so the shrinkage will be significantly lower.| Wood species | Radial shrinkage (%) | Tangential shrinkage (%) |

| Ash | 5,0 | 8,0 |

| Birch | 5,3 | 7,8 |

| Beech | 5,8 | 11,8 |

| Oak | 4,0 | 7,8 |

| Lime | 5,5 | 9,1 |

| Maple/td> | 3,2 | 8,4 |

| Common alder | 4,4 | 7,3 |

| Norway spruce | 3,6 | 7,8 |

| Scotch pine | 4,0 | 7,7 |

Natural moisture content

When the wood is green/fresh, the moisture content is very high. After the tree has been felled, the moisture content drops until it reaches a more or less constant level in equilibrium with the surroundings. If the wood is kiln dried, it is possible to remove all water and obtain a moisture content of 0 %. This isn't done because 'dry wood' has a natural content of water.When dried outdors (sheltered), the equilibrium moisture content is about 15-25 % depending on temperature and primarily on air humidity. If the wood is dried in a heated room, the equilibrium moisture content will be about 7-12 %, sometimes even lower, again depending on temperature and primarily on air humidity.

Because the wood may warp when it dries or absorps water, it is important that the wood has the equilibrium moisture content for the surroundings the final product is going to be used in before the wood is made to the final product. Otherwise, the finished product may warp afterwards, when the moisture content of the wood changes to fit the surroundings where it is placed.

The shrinkage may also be utilized. Most common is the use of a dry tenon and a mortise in wood with higher moisture content. When drying, the mortise shrinks and holds firmly the tenon. A possibility for woodturning is to turn a bowl in fresh wood. After drying, the bowl will be oval which can't usually be obtained from the lathe.

As mentioned, the natural moisture content is mainly determined by the humitidity of the surrounding air and also the temperature. The air humidity in heated rooms varies significantly during the year and the temperature may also vary. Outdoors it is even more pronounced. Therefore, the moisture content of the wood will change during the year, even for 'dry' wood. During the winter, the air humidity is very low in heated rooms and so the moisture content of the wood drops and the wood shrinks. In the summer, the wood absorps water and expands even in a heated 'dry' room. The change in size of the wood isn't big but it is still important - for example, drawers or doors may be difficult to open in the summer.

Definition of moisture content of wood in %

Wood may have a moisture content of more than 100 %! How is this possible? Because of the way the moisture content is calculated. It is actually a relative moisture content: weight of the moisture relative to the weight of the fully dried wood, i.e. weight of moisture divided by weight of the fully dried wood times 100 %.Green wood may contain more water than the weight of the fully dry wood itself and so, the (relative) moisture content becomes higher than 100 %

If you have a piece of wood, the moisture content can be determined by weighing the piece. Thereafter the piece is placed in an oven at a little more than 100 °C until the weight doesn't decrease further. It may take several hours or even days. Then, the (relative) moisture content can be calculated as:

Moisture content = (weight undried - weight fully dry) / weight fully dry * 100 %

Litterature:

Thomas Thomassen: "Træ og træmaterialer", DTI Træteknik, 1977, 5. udg. 1995, ISBN 87-7756-423-5.Michael O'Donnel: "Turning Green Wood", Guild of Master Craftsman Publications Ltd, 2000, ISBN 1 86108 089 1.

R. Bruce Hoadley: "Understanding Wood 2nd edition", The Taunton Press, 2000, ISBN 1-56158-358-8.

Paul Bertorelli (ed.): "Fine Woodworking" on Wood and How to Dry It", The Taunton Press, 1986, ISBN 0-918804-54-X.

| Search this site: |